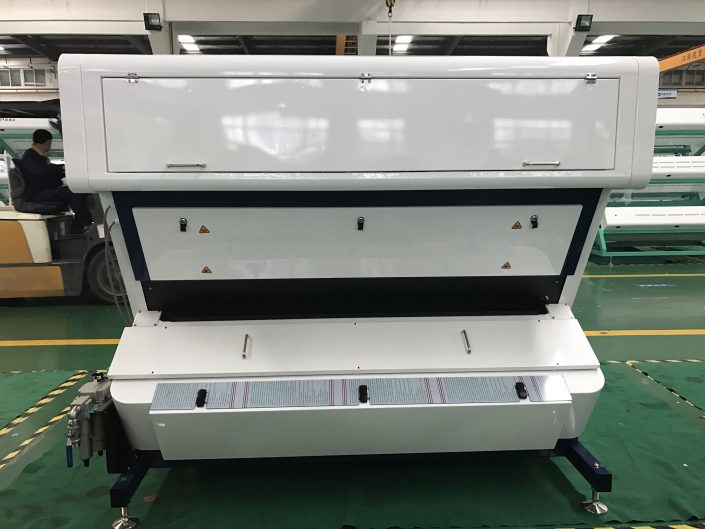

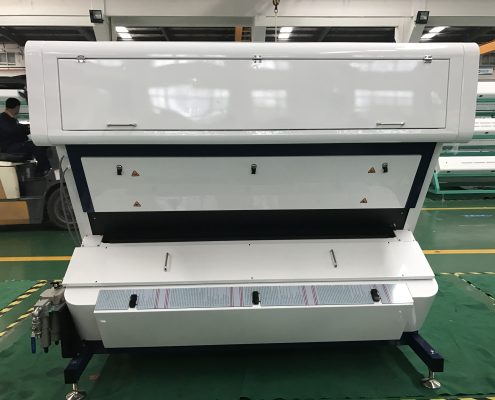

Color Sorter Machine RCZ

RC Series Color Sorter Machine: RCZ1, RCZ2, RCZ5, RCZ7, RCZ8, RCZ10, RCZ12

Specification Data:

| Model | RCZ1 | RCZ2 | RCZ5 | RCZ7 | RCZ8 | RCZ10 | RCZ12 |

| Output(t/h) | 0.5-3 | 1-6 | 2.5-15 | 3.5-21 | 4-23 | 5-30 | 4-25 |

| Carryover Rate(Bad:Good) | >10:1 | >10:1 | >10:1 | >10:1 | >10:1 | >10:1 | >10:1 |

| Sorting Accuracy(%) | ≥99.99% | ≥99.99% | ≥99.99% | ≥99.99% | ≥99.99% | ≥99.99% | ≥99.99% |

| Power Supply(V/Hz) | AC220V/50HZ | AC220V/50HZ | AC220V/50HZ | AC220V/50HZ | AC220V/50HZ | AC220V/50HZ | AC220V/50HZ |

| Power (Kw) | 0.3~0.5KW | 0.4~0.65KW | 0.7~1.1KW | 1.1~1.9KW | 1.3~2.2KW | 1.4~2.3KW | 1.5~2.5KW |

| Weight (Kg) | 350 | 500 | 1100 | 1350 | 1500 | 1750 | 1900 |

| Dimension (mm) | 1141*1576*1927 | 1456*1576*1927 | 2307*1549*1719 | 2937*1549*1719 | 3252*1549*1719 | 4045*1549*1719 | 4045*1549*1719 |

Full Color CCD RCZ Series Color Sorter Machine Features:

Ejectors:

Independent developed intelligent magnetic control

high-frequency ejector has no air leakage problem thanks to

the replacement of intelligent lever flexible return technology

for traditional pressure return technology.

Cloud Interconnection System

Cloud service technical platform, remote control, operation, maintenance, software upgrade can be achieved and it can detect and solve the LED light, electronic, mechanical and adjustment problems. It also can provide real-time online tracking service for the machine operation

monitoring,data acquisition and online instruction.

One Key Intelligent Operation System

The users can set the area of the material color, shape, size and defect by themselves and confirm the rejected material, so the machine can automatically set the sorting solution of the material according to the independent calculating, intelligent recognition and intelligent sorting principles with one key intelligent control technology.

Intelligent Visual Image Capture System

It can realize the visual dynamic image capture system by adopting the high resolution full color CCD sensor and low distortion lens.

Intelligent LED Light Control System

It can adjust the brightness of the LED automatically according to the material sorting requirements and environment changing due to advanced digital automatic LED light adjustment technology. The best sorting performance will be achieved.

Key Components and Brand:

Toshiba brand Full Color Camera CCD with 5400 pixel

Phoenix brand customized industrial lens

Intel and ATI brand DSP, FPGA and chips

Mean Well brand power supply

Advantec brand display

NEC brand touch screen

SMC brand filters

Schneider brand power switch.

Recommended Applications:

Rice

Wheat

Peanuts

Seeds

Grains

Beans and Pulses

Packaging & Shipping

Machines to be carefully packaged to endure transportation under harsh conditions. Handling instructions are designed to protect the machine in the critical moments during transportation, unloading and installation.

Delivery Time: 20- 30 Days after order confirmed.

Payment Terms: TT, Letter of Credit.

Commissioning and Installation:

1. On Site Installation and Training Service by our professional engineer ;

2. Study and Learn the Machine Operation in Our Factory.

3. Responsive in 24 hours: Telephone, Email, Video or On Site Solutions by our Technical Experts.

After Sales Services:

• With presence in a variety of countries, Metak is strongly committed to being close to the customer.

• Through cooperation with loyal and carefully evaluated and trained local employees and partners, Metak managed to provide fast, competent and rooted services in the context of customers.

• Application center in Hefei production base offer demo machines for tests and comparison.

• A strong central technical team in Hefei is supporting local channels with training, advice and technical support.

• Under normal working circumstances, Metak machines enjoy 1 year of full warranty and a lifelong warranty on the machine structure upon the date of purchase.

• Service line is available for emergency support.

• Metak products will be serviced and supported wherever customers are located.

• Through the global Metak network and from Metak technical experts, training on Metak machines is available worldwide.

How does the Metak Color Sorting Machine Work?

According to the different color selection of materials, detecting the colors of the granular materials that pass before them, and using mechanical or pneumatic ejection devices to divert the material whose colors do not fall within the acceptable range.

Suitable sorting and grading: All peanuts, rice, wheat, etc..

How Can We Help you?

Improving your profitability:

Highest quality production

Lowest product loss

Diverse products, any contaminant

Minimal product damage

Low operating costs – long term warranty

Optimum recovery rates

Enhancing your productivity:

Minimum operator skills

High uptime

Quick and easy installation

Maintenance from remote locations

For consistency in production

Effective in harshest environments

Get Your Solutions with Metak Color Sorter Machine, Inquiry us NOW!