Ore CCD Color Sorting Machine

Ore CCD Color Sorting Machine

Technology Data:

|

Model |

OCSS1280 |

|

|

Layer No. |

Double |

|

|

Output (T/h) |

2-5cm |

9-17 |

|

4-8 Mesh |

7-10 |

|

|

10-16 Mesh |

4-6 |

|

|

20-30 Mesh |

1.5-3.5 |

|

|

30-40 Mesh |

1-2 |

|

|

Carryover (bad: good) |

≥20:1 |

|

|

Accuracy (%) |

≥99% |

|

|

Voltage (V/Hz) |

220V/50HZ |

|

|

Power (Kw) |

3.5-7 |

|

|

Air pressure (Mpa) |

0.6-0.8 |

|

|

Consumption (L/min) |

2000-2800 |

|

|

Weight (Kg) |

1700 |

|

|

Dimensions (mm) |

2500*2030*2590 |

|

Ore CCD Color Sorting Machine Features:

1, the introduction of LED Air Cooling

1. Application of air-cooled system

The application of air-cooled system has solved the problems of high temperature, heavy energy loss and short service life – all of which were caused by longtime utilization of an LED light source, ensuring the durability of an LED light source under a constant temperature.

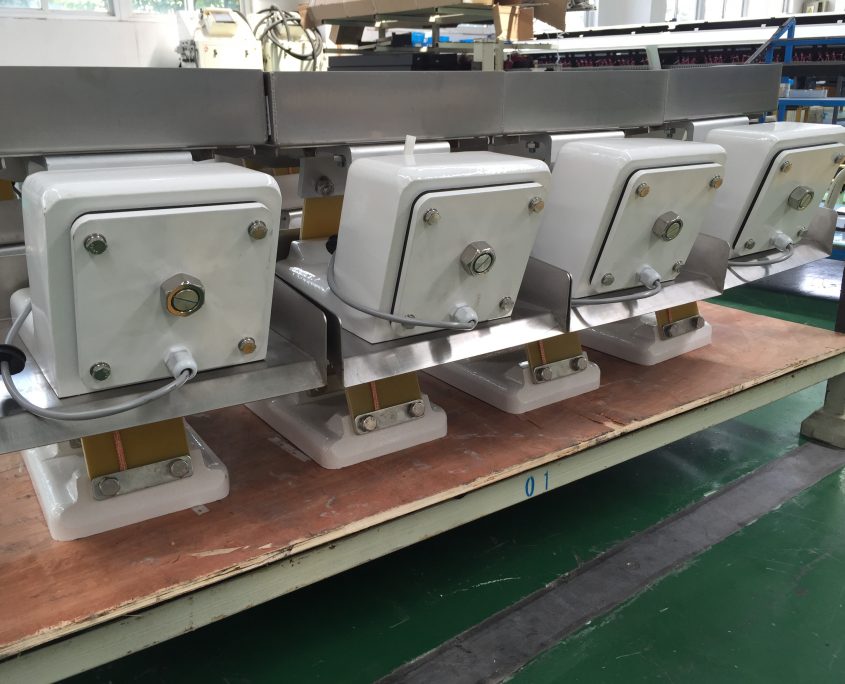

2. Color image acquisition system

Using high-definition color CCD camera image acquisition system, to achieve material (RGB) red, green and blue three color information acquiring, depth recognition tiny fine color sorter can choose other impurities. Transparent or non transparent selection of transparent material.

3. Cloud object link system

Autonomous cloud control, cloud computing technology, the realization of online operations, online monitoring, online services, free upgrades.

4. Image processing system

International high-end color line scan technology, the International frontiers of DSP+FPGA processing technology, CCD reached 5400 X 10K scan capture, color and shape of the combination of a variety of models of complex intelligent algorithm, for different ore materials provide “the color selection and shape selective penetration of the solution.

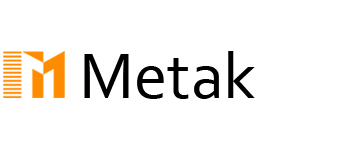

5. Solenoid Valves

The only independently developed dedicated solenoid valves with independent intellectual property rights for color sorters in the industry; special high-strength materials, strong suction, no residual magnetism, linear flow, precise blow, high consistency, significantly lowered optimal carryover; gas consumption for removing 1 ton materials is reduced by 20-30%; the frequency can be up to 1200hz per second, the fastest response time is within 0.5m/s, the service life is 5-10 billion times.

6. Operating system

With intelligent operating platform, the system can be mastered and operated easily, turning the intelligent communication between human and machine into reality and eliminating all your concerns about operating.

7. Light source processing system

Using LED light source background board, intelligent flexible conversion of the background light RGB color, set more simple.

8. Circulating ash cleaning system

Round high-strength glass, 360 degree automatic rotation cleaning, without shutdown timer cleaning, improve the efficiency of the machine and sorting effect.

9. Dust removal system

The original dust removal system, can remove raw material attached to the ethereal matter, dust automatic winnowing, effectively enhance the color sorting accuracy and effectiveness.

10. Double sorting mode

According to the different needs of customers can be set flexibly realize the sorting can lower again to check, no need to replace the function of the hopper.

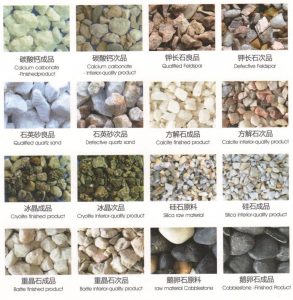

Example of Sorting:

Packaging & Shipping

Machines to be carefully packaged to endure transportation under harsh conditions. Handling instructions are designed to protect the machine in the critical moments during transportation, unloading and installation.

Delivery Time: 20- 30 Days after order confirmed.

Payment Terms: TT, Letter of Credit.

Commissioning and Installation:

1. On Site Installation and Training Service by our professional engineer ;

2. Study and Learn the Machine Operation in Our Factory.

3. Responsive in 24 hours: Telephone, Email, Video or On Site Solutions by our Technical Experts.

After Sales Services:

• With presence in a variety of countries, Metak is strongly committed to being close to the customer.

• Through cooperation with loyal and carefully evaluated and trained local employees and partners, Metak managed to provide fast, competent and rooted services in the context of customers.

• Application center in Hefei production base offer demo machines for tests and comparison.

• A strong central technical team in Hefei is supporting local channels with training, advice and technical support.

• Under normal working circumstances, Metak machines enjoy 1 year of full warranty and a lifelong warranty on the machine structure upon the date of purchase.

• Service line is available for emergency support.

• Metak products will be serviced and supported wherever customers are located.

• Through the global Metak network and from Metak technical experts, training on Metak machines is available worldwide.

Ore Sorter Machine Working Video

How does the Metak Ore Sorting Machine Work?

According to the different color selection of materials, detecting the colors of the granular materials that pass before them, and using mechanical or pneumatic ejection devices to divert the material whose colors do not fall within the acceptable range.

Suitable sorting and grading: All Ore.

How Metak Ore Sorter Machine Can Help you?

Improving your profitability:

Highest quality production

Lowest product loss

Diverse products, any contaminant

Minimal product damage

Low operating costs – long term warranty

Optimum recovery rates

Enhancing your productivity:

Minimum operator skills

High uptime

Quick and easy installation

Maintenance from remote locations

For consistency in production

Effective in harshest environments

Get Your Solutions with Metak Ore Color Sorter Machine, Inquiry us NOW!